Nanodiamonds,

since their inception, are finding their way into different applications like

cosmetics, coatings, quantum sensing, tools and equipment, electronics,

biomedical, and various others. They are getting immense popularity as they

come with several sought-after properties and qualities which cannot be

obtained through other materials. While their application is becoming more diverse,

their nanodiamond coating application is still highly preferred in the

industry.

So,

this post is being shared with you to discuss what nanodiamonds are and what

makes them suitable for coating application.

What

are Nanodiamonds?

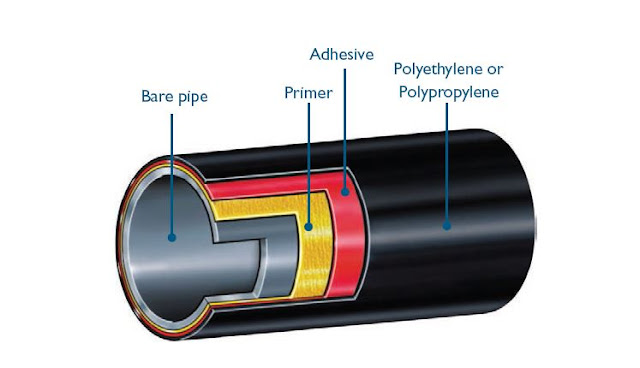

Technically,

carbon nanodiamonds consist of a complex structure as its inner core is made up

of diamond and the outer part is made of amorphous carbon shell. They belong to

the group of zero-dimensional carbon nanoallotrope and have diamondoid like

monocrystalline topology with crystal domains and complex structure.

Generally

speaking, they are the diamonds whose size range in nanoscale. The availability

of such smaller particles with extreme tough core is definitely an immediate

advantage which can be exploited in many ways. The common way of producing

nanodiamonds is chemical vapor deposition.

Due

to their unique structure, they possess a wide array of unique properties such

as:

- Extreme

hardness

- High

surface area

- Mechanical

robustness

- High

electrochemical stability

- Excellent

thermal conductivity

- Environmental

inertness

- Optimum

insulating property

- Non-toxicity

- Biocompatibility

What Makes Nanodiamonds Suitable for Coating Applications?

Physical

properties like hardness, friction wear and tear properties, and thermal

conductivity are now available to the coating industry because of the

nanodiamonds.

Since

these properties of nanodiamonds are so different than most materials,

engineers need only a small loading of nanoscale diamond particles to

dramatically change the properties of existing materials.

Improvements

of up to 60% in surface coating properties such as wear resistance, coefficient

of friction and thermal conductivity can be obtained by adding a few percent by

weight of nanodiamond material and in some cases as small as 0.1%.

The

improvement in coating performance comes in part from the presence of

nanodiamonds - hardwearing particles integrated into the polymers. However,

there is also a change in the overall structure of the coating, for instance,

the crack structures are finer and smaller in size, surface finish measurement

is lower about 85%, and the surface appears smoother and somewhat glossy.

Therefore,

nanodiamond coating is widely preferred for the coating of materials

where we need to enhance their properties like strength, wear resistance,

abrasion resistance, and durability.

In

nickel and gold electroplating, a high improvement in wear resistance can be

achieved with just fractional quantities of nanodiamonds while using

agglomerated suspensions.

The

current improvement in nanodiamond-polymer is focused on friction and wear

properties to achieve greater results in surface coatings and creating

thermally conductive polymers for thermal management applications in LED

lighting and electronics.