Metals usually get corroded in case they are kept in such an atmosphere where the dampness in the air is more, moreover, the corrosion would be more if they are kept in such environment for a longer time span. That is why, it is important to add a metallic coating on any kind of metallic part or tool to protect it from corrosion and to improve its conductivity.

There are some certain methods and techniques to add a guarding layer of metal on the part. Physical vapor deposition is the most commonly used method to add metallic layer to a series of metallic parts and tolls in order to make it strong enough to bear wear and tear.

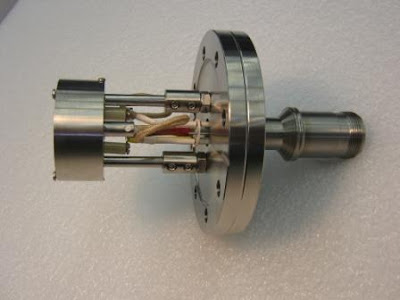

The inconel substrate heater is an essential part of some specific kinds of vapor deposition processes such as thermal evaporation, chemical vapor deposition, reactive sputtering, pulsed laser deposition and some more. The heater is generally made oxygen compatible which is especially designed for thin layer oxide based vacuum applications and processes. The best thing about such heaters is that they deliver accurate temperature and uniformed heating during the process of vapor deposition.

The Method of Vapor Deposition:

It is a method in which a thin-film of anti-oxidant material is deposited that wouldn’t degrade other properties of the metal. There are basically two mainstream methods of vapor deposition which are physical method and chemical method. Physical deposition method is capable of using any material that can be coated on the metal part or tool and is more environment friendly than the chemical method. The main purpose of coating the part is to prevent galling and to save money by not buying new tools or parts.

Physical Vapor Deposition: Physical deposition is considered as better and harder coating solution to prevent corrosion and physical depreciation. It increases lubricity and enhances release. Here also, the inconel substrate heater is vital to proceed with some certain types of physical deposition processes. During the process, there’s no requirement of chemicals and degrading their properties. It is highly preferred due to the hardness and resistance that is achieved after deposition. Titanium and other compounds of it are popularly used as coating materials. There are some additional compounds of titanium which are preferably used in some processes where the color of metal is required. For instance, the dies and screws which look like they are made of brass, generally are made of titanium compound coated over the metallic surface.

Chemical vapor deposition: In this process, a chemical (in a gaseous state) is deposited over the metal part surface. The gas is delivered into the reaction chamber where inconel substrate heater heats it up at a specific temperature according to the requirement to perform chemical reaction. Later, the gas condenses and solidifies as a thin layer over the metal when it comes in contact with the metal part.

The materials which are used as coating sources are carbon fiber, monocrystalline, carbon nanotubes, silicon, and silicon germanium, etc. Vapor deposition is generally utilized to produce optical fibers, semi-conductors, synthetic diamonds and nano machines, etc.