Thin Film Deposition is a vacuum innovation and technology for applying coatings of unadulterated materials to the surface of different objects. The coatings, likewise called films, are as a rule in the thickness scope of angstroms to microns and can be a solitary material, or can be numerous materials in a layered structure. This paper talks about the fundamental standards of thickness and rate control by utilization of quartz crystal observing.

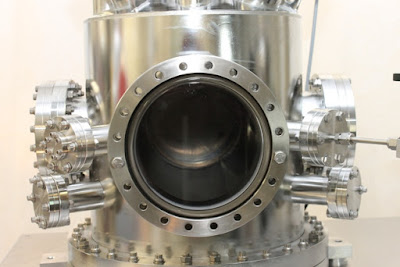

One important class of deposition procedures is evaporation, which includes warming a strong material inside a high vacuum chamber, taking it to a temperature which creates some vapor weight. Inside the vacuum, even a generally low vapor weight is adequate to raise a vapor cloud inside the chamber. This vanished material consolidates on surfaces in the chamber as a covering or "film". This technique, including the general kind of chamber plans regularly utilized for it, is a brilliant possibility for effective control of rate and thickness using quartz precious crystals.

The key idea driving this sort of estimation and control is that an oscillator crystal can be reasonably mounted inside the vacuum chamber to get statement continuously and be influenced by it quantifiably. Particularly the wavering recurrence will drop as the precious stone's mass is expanded by the material being stored on it. To finish the estimation system, an electronic instrument constantly peruses the recurrence and performs fitting numerical capacities to change over that recurrence information to thickness information, both momentary rate and cumulated thickness.

Such sensors and instruments are promptly financially accessible, incorporating into a coordinated bundle that not just peruses and shows the rate and thickness information, yet additionally gives yields to other deposition system components. It will have a simple drive signals to drive the source control supply in a closed loop procedure on the basis of rate information and accordingly can keep up a preset rate during deposition. What's more, it will have different yields to interface with capacities, for example, a source shutter triggered to close when the preset last thickness is accomplished.

The first ramp up is generally slower and stops at some level just beneath vaporization and holds it to accomplish an adequate level of balance before making the second ramp up to vaporization. The last ought to in a perfect world be the real power level for the coveted testimony rate, and as a rule, since you will now devour material and covering the base of the shutter, this second ramp and soak is made genuinely short. However, those points of interest are client decisions. The controller gives you a chance to choose how you need it.

While it is conceivable to utilize this same crystal observing and control innovation and technology in a sputtering system, it is entirely improved the situation a few reasons, one of which is that testimony rate versus cathode drive control is normally satisfactorily stable for process control in sputtering. Likewise, common sputter chambers are less manageable to situating crystals, and plasma can meddle with them.