The chemical vapor disposition (CVD) diamond advanced out of decades-old procedures created amid the 1950s. It is interesting to note that an idea that is in certainty decades old is to some degree still used in a modern procedure of diamond manufacturing.

A significant part of the engineered diamond industry relies on a procedure known as HPHT or high-pressure high-temperature process. In spite of the fact that this technique is viewed as the highly followed procedure for developing diamonds in the present business and still remains the essential assembling process, a decades-old process is as yet exist in the business for making a remarkable assortment of shapes and films which address the requirements of an interminable cluster of industries.

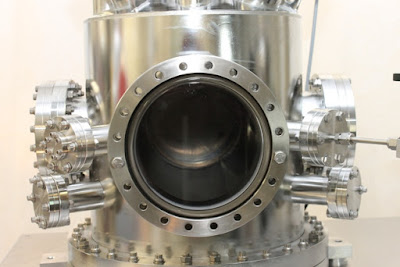

The procedure is known as the chemical vapor disposition which develops diamonds through the procedure of low pressure, a direct inverse strategy interestingly with HPHT. The low-pressure process was introduced and developed in the 1950s and still utilized today for numerous other current techniques that are developing around this deep-rooted idea came into existence long back.

The way toward the manufacturing of diamonds through the low-pressure procedure of deteriorating carbon along with CVD diamond coatings gives new chances to produce units of diamonds in various shapes and different characteristics that completely utilize capabilities of the diamond.

The significance of CVD process is that it can provide the same result of HPHT without the high pressures that are required during the HPHT procedure. The CVD procedure brings about delivering an immense range of diamonds which are essential for some designing applications through a low-pressure process. An interesting certainty about the CVD diamond is that in the meantime the low-pressure technique was being utilized; General Electric was building up the HPHT method effectively. The company attempted a few methods for creating the CVD diamond by means of the low-pressure technique. After some failed attempts, they left the idea and kept on developing diamonds through the HPHT method.

General Electric's endeavors at the low-pressure technique were being led before Union Carbide effectively finishing their trial attempt at low-pressure manufacturing. Following the victory by Union Carbide, Japanese researchers found a technique for developing diamonds at a quick pace through low-pressure procedures. This brought about a noteworthy achievement in the mass production of the CVD diamond and considered as a remarkable point for many diamond businesses in this industry.

At first, it made numerous industries set unreasonable objectives for the diamond electronic items, however, the thought got on and other agencies started manufacturing the CVD jewel. The expanded accessibility developed the diamond electronics industry and also the demand for the CVD diamond kept on growing.

More than forty years after the fact developing CVD diamonds through the low-pressure process is as yet dynamic in making numerous items helpful to the advanced industry. The CVD diamond is currently entering another stage for development in a portion of its growing procedures that will give more consistency and fewer imperfections underway. This implies accomplishing more points of reference with respect to atomic fusion research and laser speed innovation through 50 years old idea.